R2R MOTION CONTROL

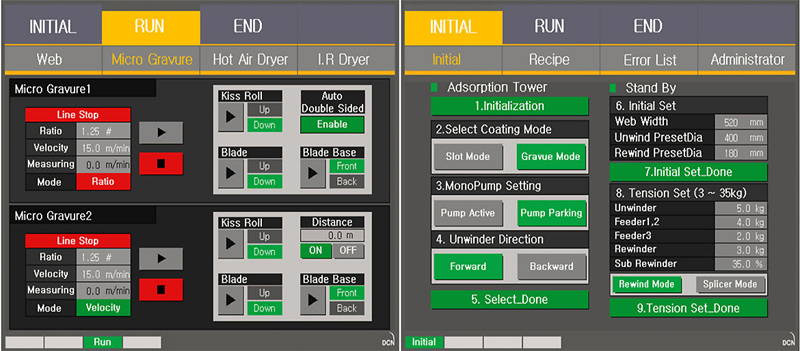

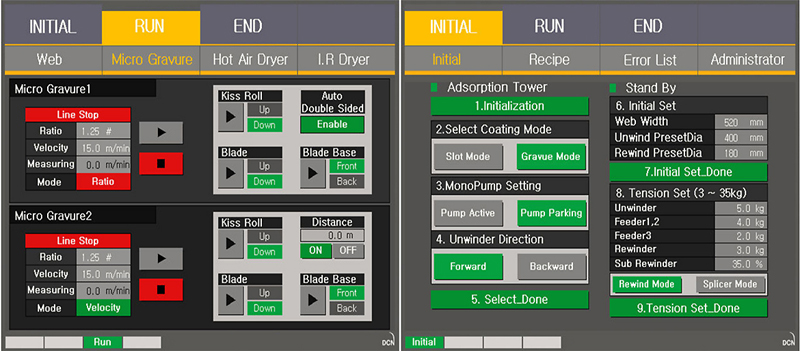

HMI using MLC program

[ Main Controller ]

Can control equipment quickly and stably by using a high-performance controller that can control servo motors of 64 axes or more without adding additional software or hardware through MLC with integrated high-performance PLC and motion controller

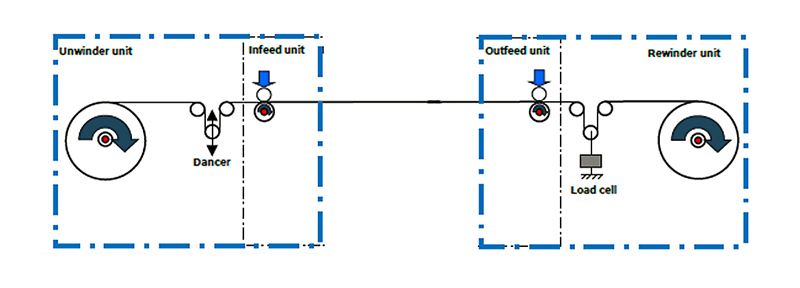

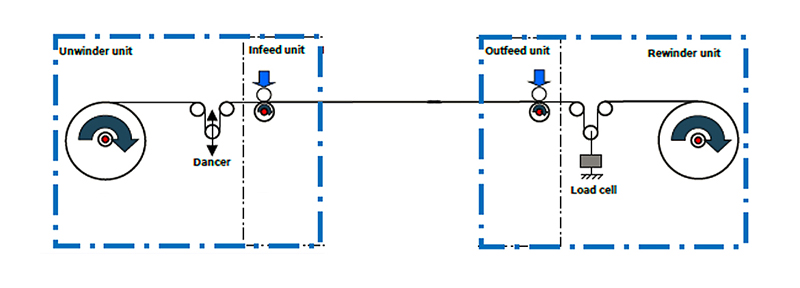

[ Virtual Axis Synchronization ]

Uses the virtual motor axis as a master, synchronizes all servo motors involved in web transfer, and runs all sections at a constant speed without deviation

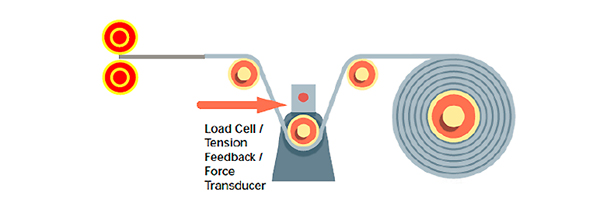

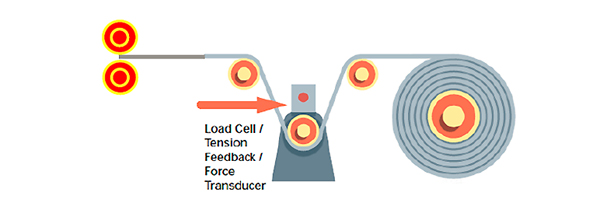

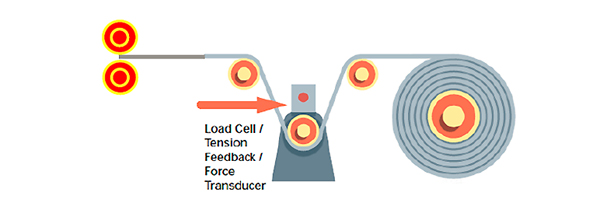

[ Tension Control ]

Tension control is performed based on virtual axis synchronization, load cell and dancer feedback. The tension of each section is kept uniform when minimizing MD direction wrinkle and web transfer. It can perform the feeding of the feeder without any buffer zone (accumulator).

[ Winder Taper Tension Control & Edge Control ]

Calculates and operates the current rewinder diameter value in real-time while driving on the web based on load cell feedback to keep roll tension constant. Perfect winding of rolls without film meandering by edge control.

HMI using MLC program

[ Main Controller ]

Can control equipment quickly and stably by using a high-performance controller that can control servo motors of 64 axes or more without adding additional software or hardware through MLC with integrated high-performance PLC and motion controller

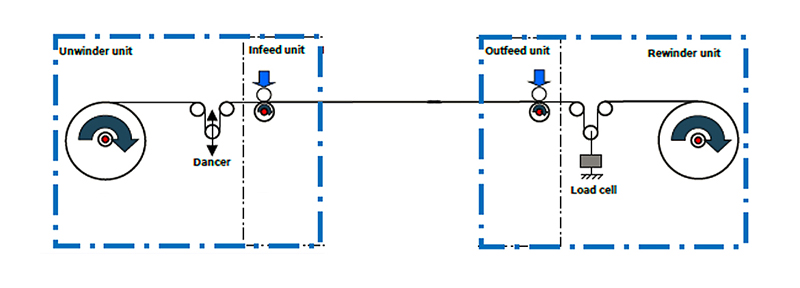

[ Virtual Axis Synchronization ]

Uses the virtual motor axis as a master, synchronizes all servo motors involved in web transfer, and runs all sections at a constant speed without deviation

[ Tension Control ]

Tension control is performed based on virtual axis synchronization, load cell and dancer feedback. The tension of each section is kept uniform when minimizing MD direction wrinkle and web transfer. It can perform the feeding of the feeder without any buffer zone (accumulator).

[ Winder Taper Tension Control & Edge Control ]

Calculates and operates the current rewinder diameter value in real-time while driving on the web based on load cell feedback to keep roll tension constant. Perfect winding of rolls without film meandering by edge control.

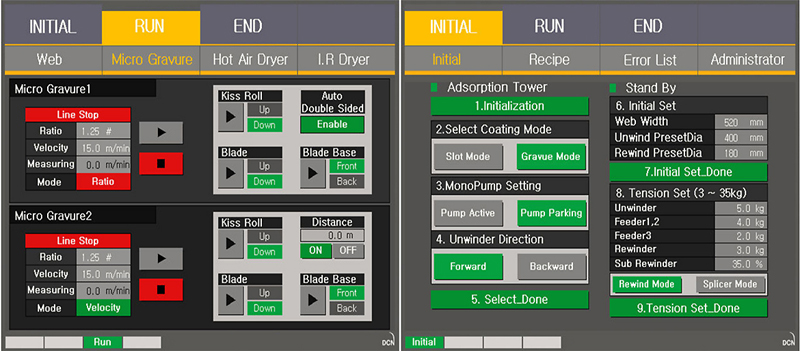

HMI using MLC program

[ Main Controller ]

Can control equipment quickly and stably by using a high-performance controller that can control servo motors of 64 axes or more without adding additional software or hardware through MLC with integrated high-performance PLC and motion controller

[ Virtual Axis Synchronization ]

Uses the virtual motor axis as a master, synchronizes all servo motors involved in web transfer, and runs all sections at a constant speed without deviation

[ Tension Control ]

Tension control is performed based on virtual axis synchronization, load cell and dancer feedback. The tension of each section is kept uniform when minimizing MD direction wrinkle and web transfer. It can perform the feeding of the feeder without any buffer zone (accumulator).

[ Winder Taper Tension Control & Edge Control ]

Calculates and operates the current rewinder diameter value in real-time while driving on the web based on load cell feedback to keep roll tension constant. Perfect winding of rolls without film meandering by edge control.