DRYER

(Essential for wet coating)

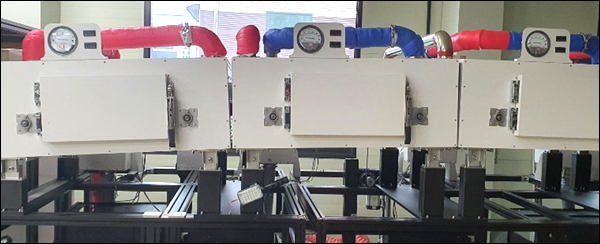

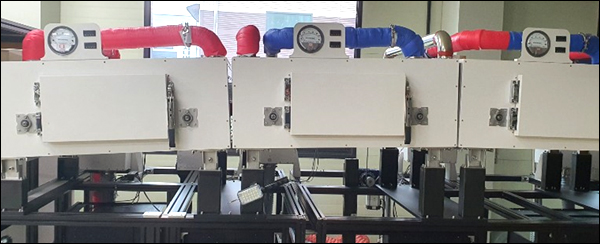

[ Drying technology ] Technology that thins materials in a liquid state during the wet process and a drying process required during the wet coating. Drying devices can be roughly divided into hot air drying, IR drying, and drying using UV. A mixed structure combining these can be designed according to the drying process and the properties of the material. The technology required for the dryer is as follows: - Uniform temperature and air speed - Cleaning of internal atmosphere - Stable operating performance, suppression of dry trouble - Energy saving |

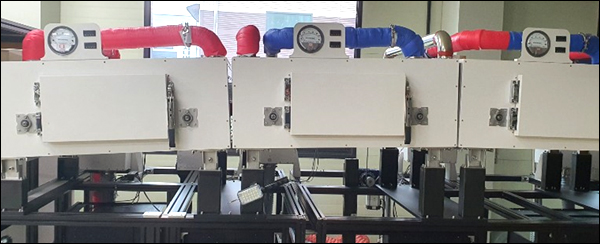

[ Features ] - PID control per each zone temperature - Derivation of the best drying method according to material and system optimization - IR Lamp arranges ceramic heaters in a lattice structure to ensure uniform heat distribution - Smooth hot air fume discharge in the chamber and prevents internal pollution - Supplying particle-free clean hot air using a high-temperature HEPA filter - Max. 150 ℃ (hot air), max. 400 ℃ (IR), 360 ~ 410nm (UV) |

Temperature stability and control

|

[ Features ] - Temperature deviation after stabilization: 135 ℃ ±1℃ - WEB left/right temperature deviation: 135 ℃ ± 2.3 % - Complexation of heat wind and IR ceramic, if necessary - Application of supply/exhaust and overcurrent monitoring and block |

|

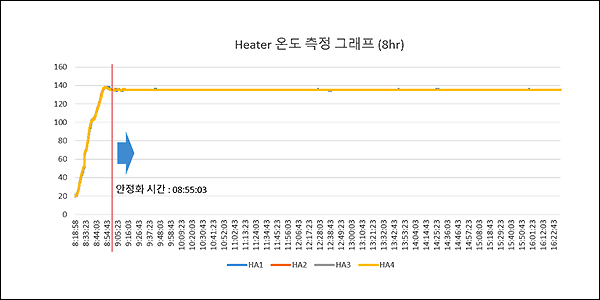

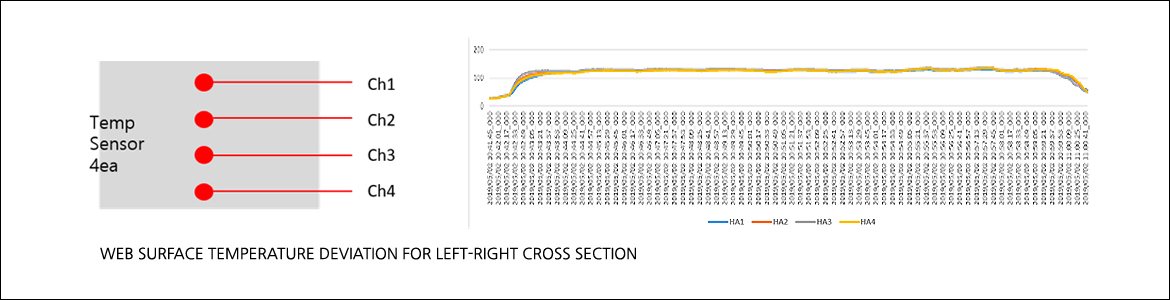

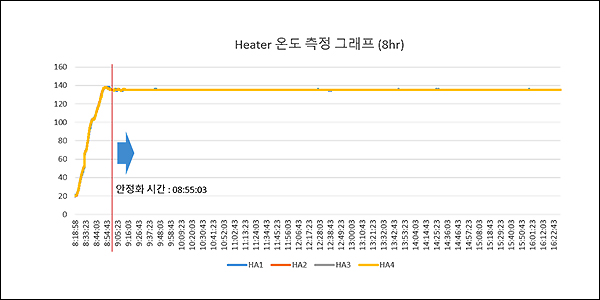

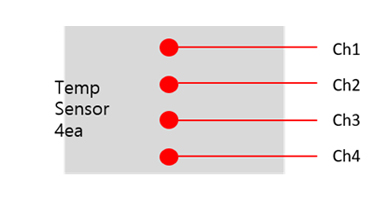

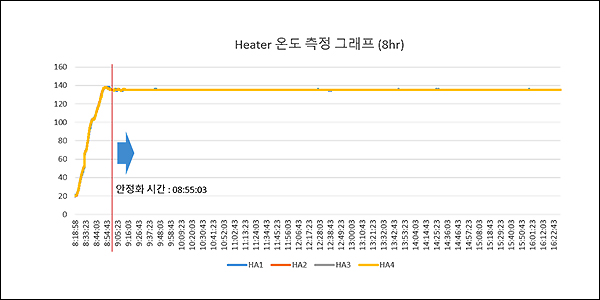

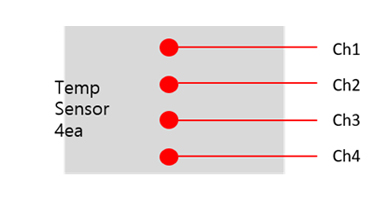

[ Temperature measurement graph ] - Atmosphere temperature measurement of each drying zone by sensor - Temperature deviation after target temperature stabilization (135℃ ±1℃)) |

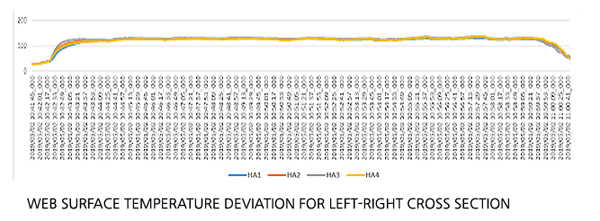

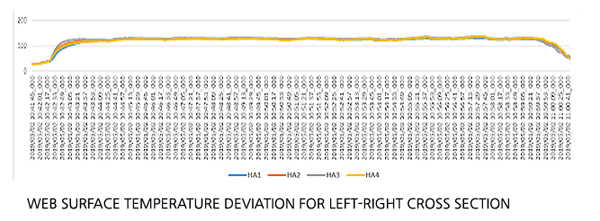

- Web surface temperature left/right deviation test for all drying zones (135 ℃ ± 2.3%)

Turning liquid into a thin film during the wet process. (Essential for wet coating)

[ Drying technology ]

Technology that thins materials in a liquid state during the wet process and a drying process required during the wet coating.

Drying devices can be roughly divided into hot air drying, IR drying, and drying using UV. A mixed structure combining these can be designed according to the drying process and the properties of the material.

The technology required for the dryer is as follows:

- Uniform temperature and air speed

- Cleaning of internal atmosphere

- Stable operating performance, suppression of dry trouble

- Energy saving

[ Features ]

- PID control per each zone temperature

- Derivation of the best drying method according to material and system optimization

- IR Lamp arranges ceramic heaters in a lattice structure to ensure uniform heat distribution

- Smooth hot air fume discharge in the chamber and prevents internal pollution

- Supplying particle-free clean hot air using a high-temperature HEPA filter

- Max. 150 ℃ (hot air), max. 400 ℃ (IR), 360 ~ 410nm (UV)

Temperature stability and control

[ Features ]

- Temperature deviation after stabilization: 135 ℃ ±1℃

- WEB left/right temperature deviation: 135 ℃ ± 2.3 %

- Complexation of heat wind and IR ceramic, if necessary

- Application of supply/exhaust and overcurrent monitoring and block

[ Temperature measurement graph ]

- Atmosphere temperature measurement of each drying zone by sensor

- Temperature deviation after target temperature stabilization (135℃ ±1℃)

- Web surface temperature left/right deviation test for all drying zones (135 ℃ ± 2.3%)

Turning liquid into a thin film during the wet process. (Essential for wet coating)

[ Drying technology ]

Technology that thins materials in a liquid state during the wet process and a drying process required during the wet coating.

Drying devices can be roughly divided into hot air drying, IR drying, and drying using UV. A mixed structure combining these can be designed according to the drying process and the properties of the material.

The technology required for the dryer is as follows:

- Uniform temperature and air speed

- Cleaning of internal atmosphere

- Stable operating performance, suppression of dry trouble

- Energy saving

[ Features ]

- PID control per each zone temperature

- Derivation of the best drying method according to material and system optimization

- IR Lamp arranges ceramic heaters in a lattice structure to ensure uniform heat distribution

- Smooth hot air fume discharge in the chamber and prevents internal pollution

- Supplying particle-free clean hot air using a high-temperature HEPA filter

- Max. 150 ℃ (hot air), max. 400 ℃ (IR), 360 ~ 410nm (UV)

Temperature stability and control

[ Features ]

- Temperature deviation after stabilization: 135 ℃ ±1℃

- WEB left/right temperature deviation: 135 ℃ ± 2.3 %

- Complexation of heat wind and IR ceramic, if necessary

- Application of supply/exhaust and overcurrent monitoring and block

[ Temperature measurement graph ]

- Atmosphere temperature measurement of each drying zone by sensor

- Temperature deviation after target temperature stabilization (135℃ ±1℃)

- Web surface temperature left/right deviation test for all drying zones (135 ℃ ± 2.3%)