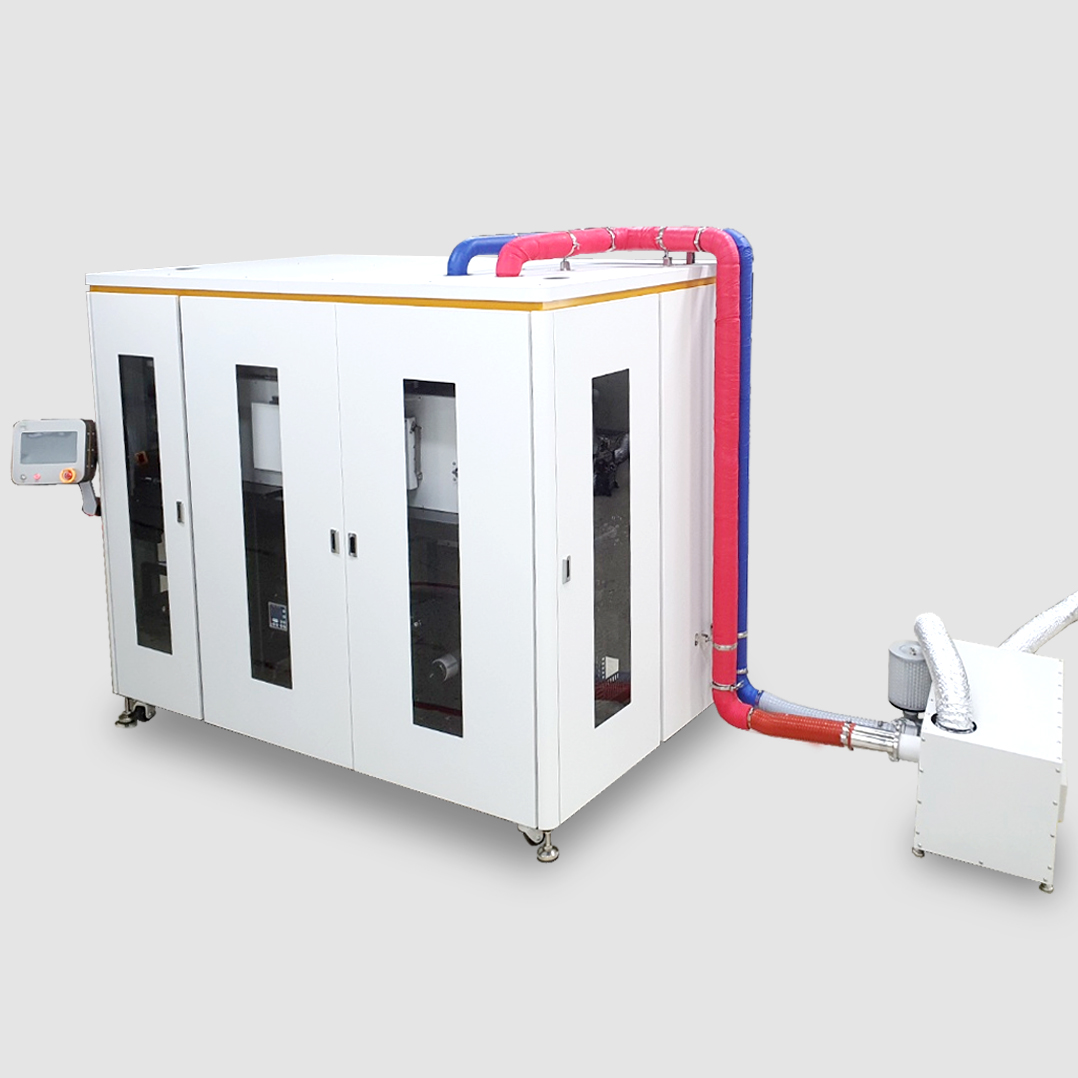

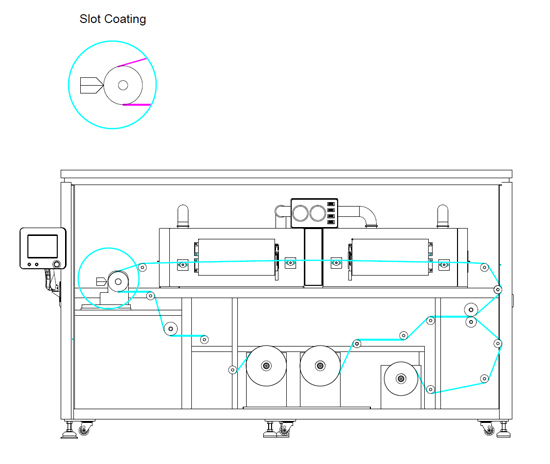

Maximum usability with materials and process development for R&D and pilot equipment in R2R process

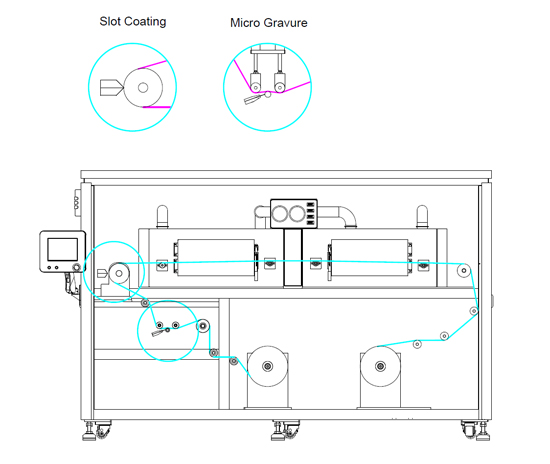

Available for various coating processes (Slot Die, Micro Gravure, Comma, Blade etc.), process optimum design according to customer needs with excellent economics and effectiveness

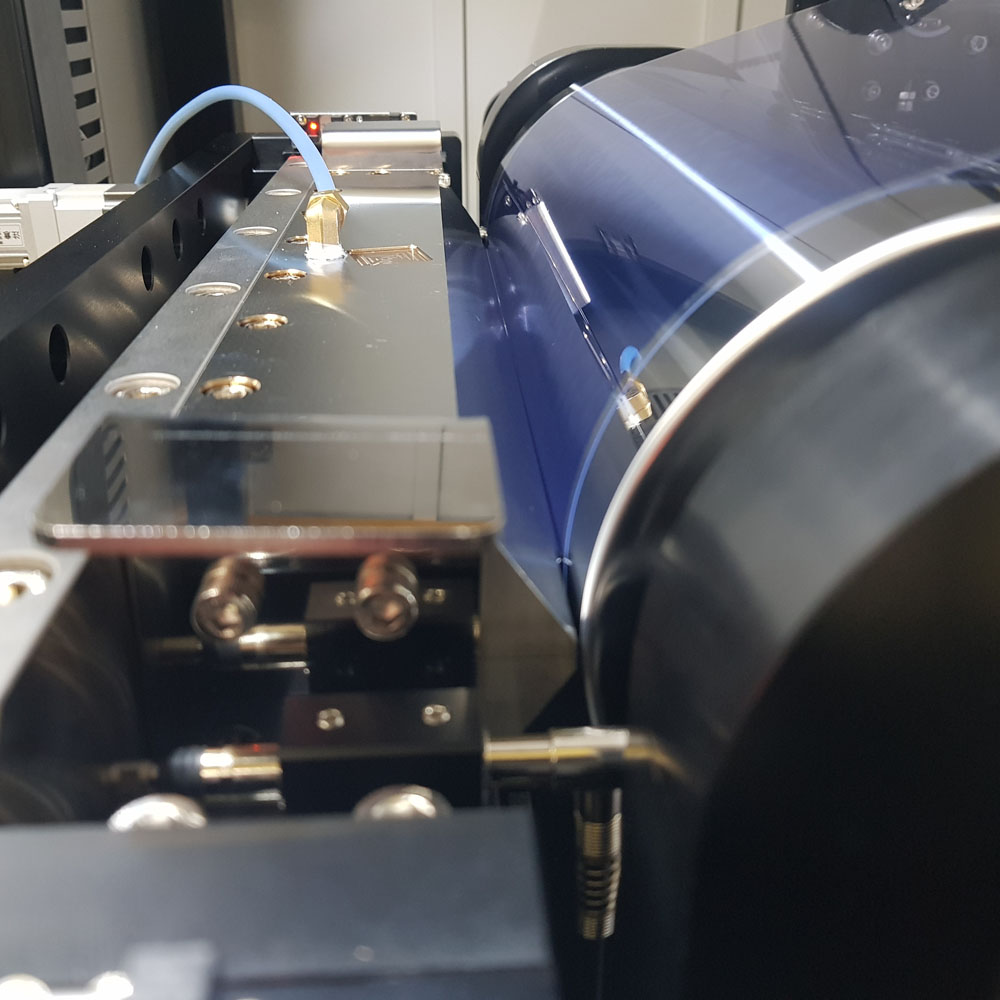

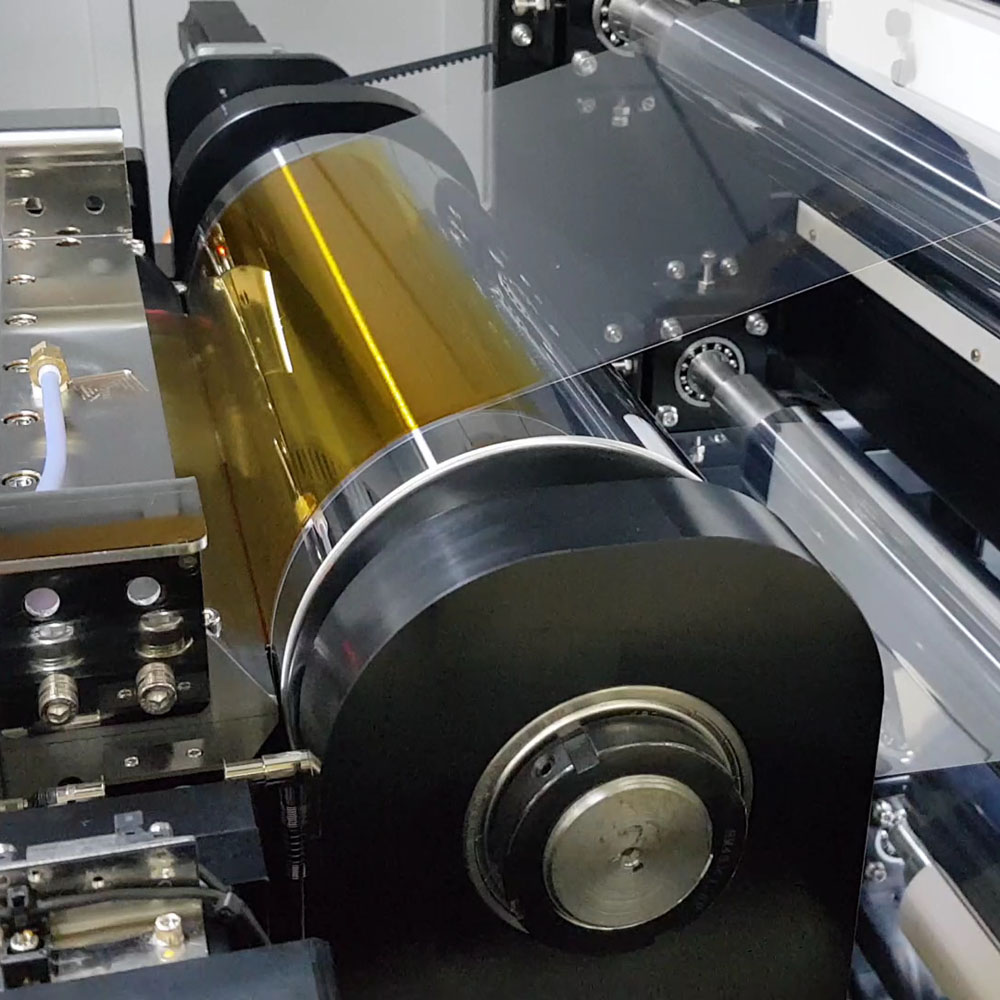

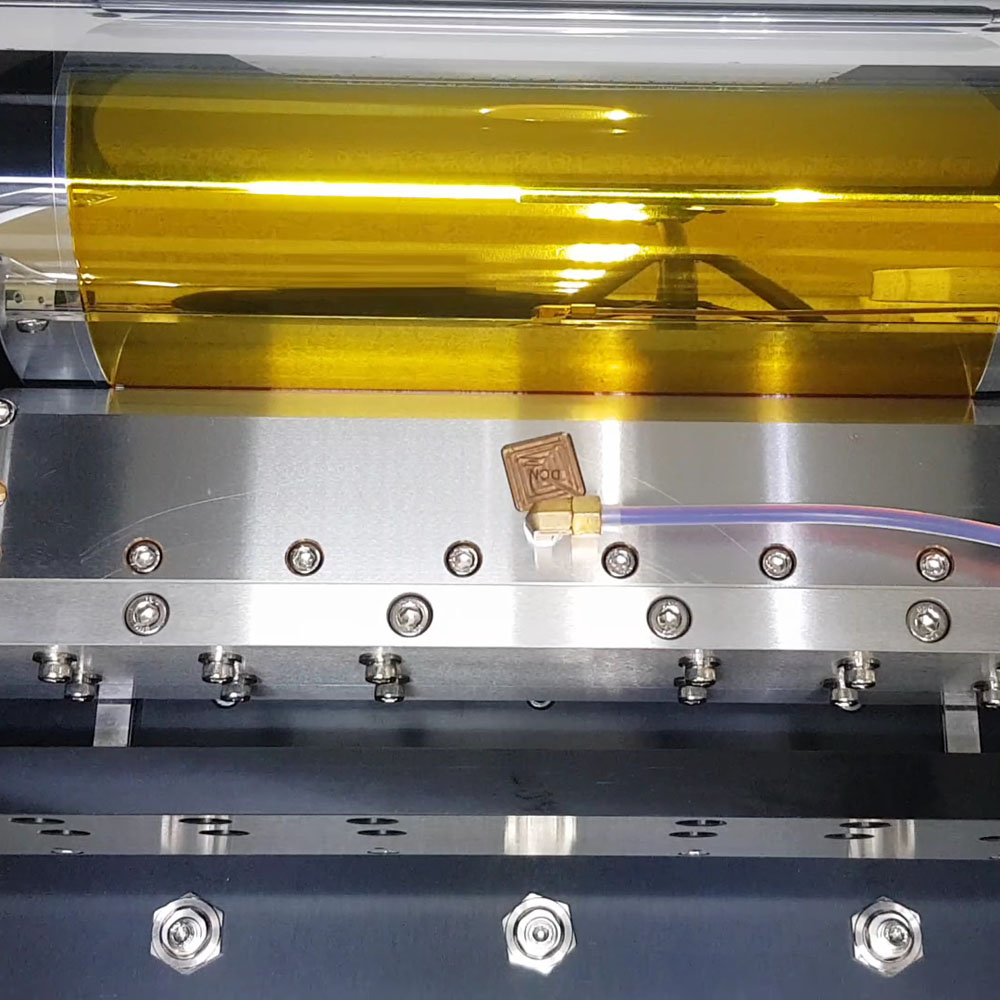

A wide range of coatings including low-viscosity thin-film coatings to high-viscosity by manufacturing the slot die itself through CFD flow analysis

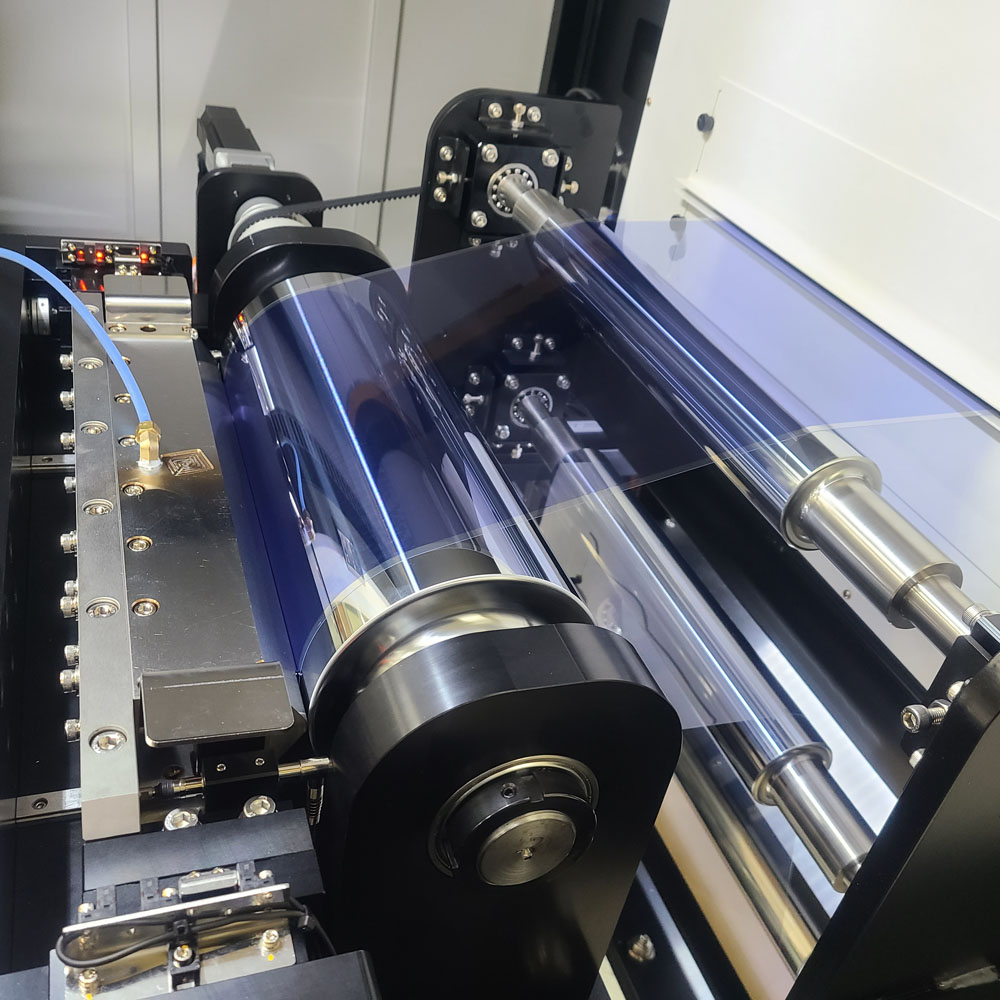

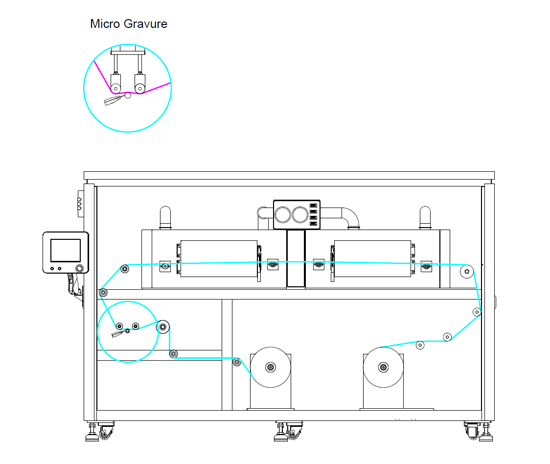

Various coating thicknesses by providing standard micro gravure roll

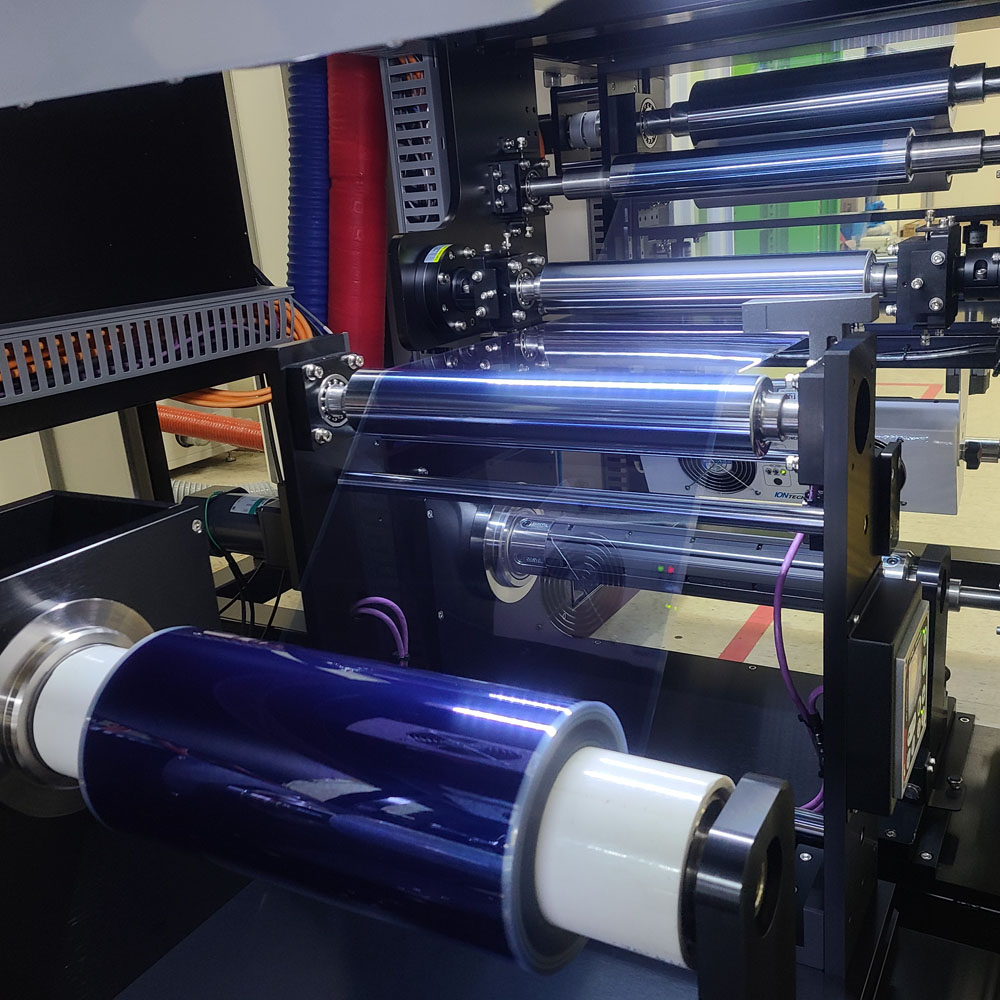

Realization of precise web transfer through speed synchronization and ability to maintain uniform web tension and control tension by section through integrated speed & tension cotrol

Stable winding system application by applying accumulated winding control technology

High temperature hot air dryer with patented technology applied and option such as UV curing, IR heater and laminator can be selected

Various pump system options available according to the physical characteristics of the material and process conditions

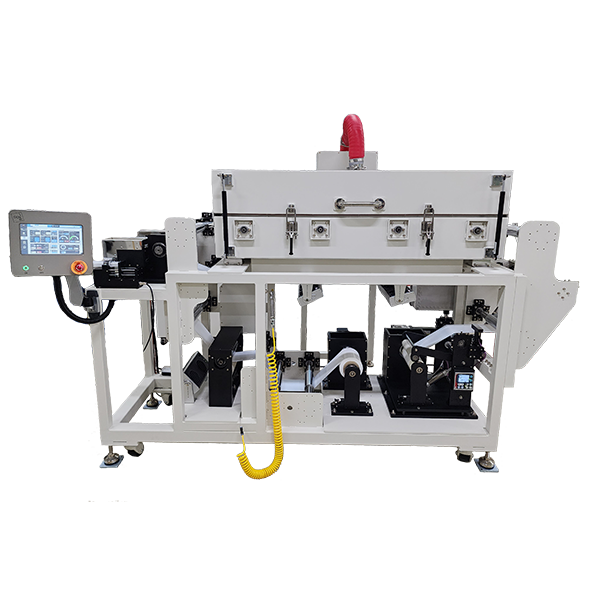

Maximum usability with materials and process development for R&D and pilot equipment in R2R process

Available for various coating processes (Slot Die, Micro Gravure, Comma, Blade etc.), process optimum design according to customer needs with excellent economics and effectiveness

A wide range of coatings including low-viscosity thin-film coatings to high-viscosity by manufacturing the slot die itself through CFD flow analysis

Various coating thicknesses by providing standard micro gravure roll

Realization of precise web transfer through speed synchronization and ability to maintain uniform web tension and control tension by section through integrated speed & tension control

Stable winding system application by applying accumulated winding control technology

High temperature hot air dryer with patented technology applied and options such as UV curing, IR heater and laminator can be selected

Various pump system options available according to the physical characteristics of the material and process conditions